Block Stacking

Block Stacking refers to the product unit stacked towards the top and stored in a row into a row or block. Pallets stacked with a certain height based on criteria such as the condition of pallets, including product weight, height permitted forklift and warehouse capabilities. Pallets are stored in this method can be taken with LIFO (Last In First Out). This method does not allow for pickup by the ordering date or FIFO method. Retrieving items can cause "honeycombing" where there are vacancies that can not be filled until the entire lane is empty. This method is not costly because it does not require a shelf and can be done in various types of warehouse with vast open land.Stacking Frame

Stacks of pallets with frames made from the deck and milestones that can be installed and moved if necessary. A stack of framed allows pallets to be stacked with a certain height and are especially useful when the pallets must be stored without having stacked. Many companies use a stack of framed at a time when they need the shelf while in times of increased demand. With the use of stack frames, the incidence of "honeycombing" also can occur as well as in the method of block stacking.Double-Deep Pallet Rack

Method of double deep pallet rack is a variant of the single deep rack that puts two in a single rack space. This method reduces the number of corridor needs, but are vulnerable to "honeycombing", so this method is less efficient than single deep racking. And, it takes a special forklift to be able to take two pallets at once for can place and remove pallets from the rack.

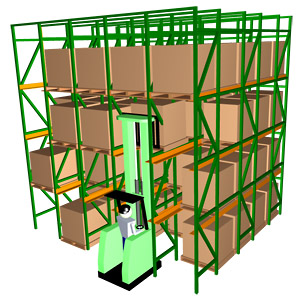

Drive In Rack

Method of drive in rack provides a place 5 to 10, which is a continuation of double deep racking. Line drive ins provide access for a forklift to place or move stock. However, the forklift has limited room for maneuver, and this requires additional time to place or retrieve pallets. This method is similar to the method of block stacking is based on LIFO.

Pallet Flow Rack

Pallet Flow Rack operates by transferring the load from one side to another with a simple conveyor so that the pallet can be moved using FIFO. When a pallet moved, then the next pallet position filled pallet moved. This method is suitable for warehouse shelves that have a high product turnover, but this option is quite expensive.Push Back Rack

Push back rack is the solution of LIFO in the which pallet loads are placed in storage by using the guide rail. When a pallet is placed in the area, the palette will from encourage other pallets into storage. When a pallet is loaded, then the palette will of shift part of the palette That occupies the place Fetched. This means EACH line of the palette has Enough wiggle room for making pallets. This method is not Suitable for warehouse use requires the FIFO method.

Cantilever Rack

Models with the concept of "Christmas Tree", cantilever rack, have flexibility in term of storage with the ability to put the product a long, strange and heavy. Iron pieces, pipes, furniture, plywood, sheet metal and Formica are appropriate goods placed on the model cantilever rack. With the continuous rack, cantilever racks suitable for placement of large boxes, furniture, etc.. Cantilever racks usually require the use of a forklift as Side loader, appliance makers special items (Special Order pickers) and trucks with 4-way achievement. (four directional reach trucks).

{ 9 comments... Views All / Send Comment! }

what an incredible web site.

This post is interested because after reading this and i get more info so i like this post and very good article. thanks for sharing

Logistic Companies | Logistics Services Bangalore

Operations such as order consolidation, order assembly, product mixing and cross-docking that take place within the warehouse structure also add value to the overall logistics system.

Top International Freight Forwarder in India|Best Supplychain Company in India

Renowned 3PLs for sure have great experience in the field and are well-versed with the best practices of the industry.

Largest warehousing company in India

Nice

Air Cargo Services in Delhi

And indeed, I’m just always astounded concerning the remarkable things served by you. Some four facts on this page are undeniably the most effective I’ve had.

iosh course in chennai

My spouse and I love your blog and find almost all of your post’s to be just what I’m looking for

nebosh course in chennai

we are professional warehouse racking systems factory .Anyone need buy ?

HELLO VIEWERS

TESTIMONY ON HOW I GOT MY LOAN $300,000.00USD FROM A FINANCE COMPANY LAST WEEK Email for immediate response: drbenjaminfinance@gmail.com

Do you need a loan to start a business or pay your debts {Dr.Benjamin Scarlett Owen} can also help you with a legit loan offer. He Has also helped some other colleagues of mine with a loan finance. Get your Blank ATM card or CREDIT CARD deliver to your doorstep that works in all ATM machines all over the world with the help of BENJAMIN LOAN FINANCE the ATM cards can be used to withdraw at the ATM Machines or swipe, at stores and POS. they give out this cards to all interested clients worldwide, If you need a loan without cost/stress he his the right loan lender to wipe away your financial problems and crisis today. BENJAMIN LOAN FINANCE holds all of the information about how to obtain money quickly and painlessly via Email drbenjaminfinance@gmail.com

THANK YOU ALL

Post a Comment